Grease pumps are essential tools in modern industrial and mechanical maintenance. They play a crucial role in ensuring that machinery operates efficiently by providing a steady and controlled supply of lubricant to moving parts. Proper lubrication reduces friction, minimizes wear and tear, and extends the lifespan of equipment. Understanding how grease pumps work, their various types, and their benefits can help businesses and maintenance professionals choose the right solution for their operations.

Understanding Grease Pumps

Grease pumps are mechanical devices designed to move lubricating grease from a container or reservoir to the lubrication points of machinery. The primary purpose of these pumps is to deliver grease under pressure, ensuring it reaches hard-to-access areas where manual lubrication might not be effective. They are commonly used in factories, workshops, construction equipment, mining operations, and automotive service centers. Grease pumps can be operated manually, pneumatically, or electrically, depending on the specific needs of the user and the scale of operations. The design of a grease pump ensures consistent pressure and accurate grease delivery, which is vital for maintaining equipment reliability and performance.

Types of Grease Pumps

There are several types of grease pumps available, each suited to particular applications and operating environments.

Manual Grease Pumps

Manual grease pumps are the simplest and most affordable type. They require human effort to operate, typically using a hand lever or handle to generate pressure. These pumps are ideal for small-scale applications, such as workshops or maintenance jobs involving limited lubrication points. While manual pumps may not deliver as much pressure as powered models, they offer great control and are easy to maintain.

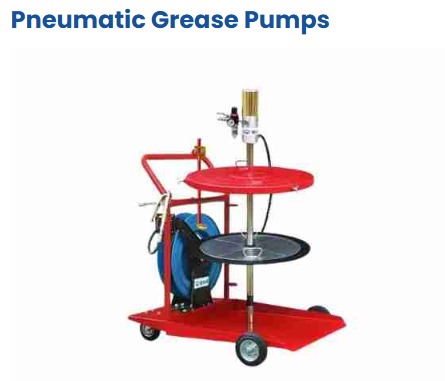

Pneumatic Grease Pumps

Pneumatic grease pumps, also known as air-operated grease pumps, use compressed air to push grease through hoses to lubrication points. These pumps are popular in industrial environments because they deliver consistent pressure and can handle high-viscosity greases with ease. They are ideal for large-scale operations where continuous lubrication is necessary, such as manufacturing plants, automotive assembly lines, and heavy-duty equipment maintenance.

Electric Grease Pumps

Electric grease pumps are powered by electricity and are suitable for automated lubrication systems. They are efficient, reliable, and capable of delivering high-pressure grease with minimal human intervention. Electric pumps are widely used in modern industries where automation and precision are key priorities. These pumps can be integrated with sensors and controllers to monitor grease levels and lubrication frequency, reducing the risk of over- or under-lubrication.

Hydraulic Grease Pumps

Hydraulic grease pumps use hydraulic pressure to move grease through the system. These pumps are typically used in applications that require high pressure and volume, such as large industrial machines or heavy construction equipment. They are known for their power and ability to deliver grease over long distances or to multiple lubrication points simultaneously.

Cordless or Battery-Operated Grease Pumps

Cordless grease pumps are portable and highly convenient for fieldwork or remote locations without access to power or air supply. They are powered by rechargeable batteries and provide the freedom to move around large facilities or job sites. These pumps combine the convenience of portability with the performance of powered lubrication systems, making them a favorite among maintenance professionals.

Applications of Grease Pumps

Grease pumps are used across a wide range of industries where machinery requires regular lubrication to function efficiently.

Automotive Industry

In automotive repair shops and service stations, grease pumps are used to lubricate vehicles’ joints, bearings, and chassis components. Regular lubrication ensures smooth vehicle performance, reduces friction, and extends the lifespan of moving parts.

Manufacturing Plants

Industrial machinery in factories relies heavily on grease pumps for continuous lubrication. Automated systems with electric or pneumatic grease pumps help maintain production lines by reducing downtime and preventing mechanical failures.

Construction and Heavy Equipment

Construction equipment such as excavators, loaders, and cranes operate in challenging environments. Grease pumps ensure that these machines’ joints, pivots, and bearings are adequately lubricated, preventing premature wear and costly repairs.

Mining and Agricultural Machinery

Mining and agricultural machines face intense working conditions, including dust, dirt, and heavy loads. Using grease pumps ensures these machines operate smoothly, maintaining efficiency even under harsh environments.

Marine and Aviation Industries

In marine and aviation sectors, grease pumps are used for lubricating critical components such as gears, bearings, and control mechanisms. Proper lubrication in these industries is vital to ensure safety and reliability.

Food and Beverage Industry

Grease pumps are also used in food processing plants, where specialized food-grade lubricants are applied to maintain machinery hygiene while preventing contamination.

Benefits of Grease Pumps

Using grease pumps offers numerous advantages, both in terms of efficiency and long-term cost savings.

1. Consistent Lubrication

Grease pumps provide consistent and accurate lubrication, ensuring that every component receives the right amount of grease. This prevents both over-lubrication and under-lubrication, which can lead to equipment damage or inefficiency.

2. Extended Equipment Life

Proper lubrication reduces friction between moving parts, minimizing wear and extending the life of machinery. Regular use of grease pumps helps prevent mechanical failures, lowering maintenance costs.

3. Increased Efficiency

Automated or powered grease pumps save time and labor, allowing technicians to lubricate multiple points quickly and efficiently. This results in improved productivity and less downtime.

4. Cost Savings

By maintaining machinery in optimal condition, grease pumps reduce the frequency of repairs and replacements. They also help avoid production losses due to mechanical breakdowns, leading to significant cost savings over time.

5. Cleaner and Safer Operation

Grease pumps minimize human contact with lubricants, promoting cleaner work environments. Many models are designed with safety features to prevent leaks and spills, reducing workplace hazards.

6. Versatility and Adaptability

Grease pumps can handle various types of lubricants and can be used across multiple industries. Whether it’s manual maintenance or fully automated systems, grease pumps are versatile tools adaptable to different requirements.

7. Environmental Benefits

Modern grease pumps are designed to minimize waste by delivering precise amounts of lubricant, reducing environmental impact. Many advanced models also support biodegradable greases, aligning with sustainable industrial practices.

Choosing the Right Grease Pump

Selecting the right grease pump depends on the scale of operations, type of equipment, and available power sources. For small workshops, manual or battery-operated pumps may be sufficient. Larger industrial setups may benefit from pneumatic or electric grease pumps for continuous and automated lubrication. It’s also important to consider grease viscosity, delivery distance, and pressure requirements before making a choice.

Conclusion

Grease pumps are indispensable tools for maintaining machinery efficiency and longevity across various industries. From manual options to fully automated systems, they offer reliable, consistent lubrication that keeps operations running smoothly. By understanding the different types, applications, and benefits of grease pumps, businesses can make informed decisions that lead to improved productivity, reduced downtime, and extended equipment life. Proper lubrication management using grease pumps is not just a maintenance practice—it’s a vital investment in long-term operational success.